The Integrated Management System introduced in BorsodChem incorporates our Environmental Management System (EMS), which is operated in accordance with requirements of the ISO 14001 standard.

All our production technologies have a unified environmental permit (Integrated Pollution Prevention and Control - IPPC). Our technology processes meet the requirements of the Best Available Techniques (BAT). Our environmental activities are in full compliance with all legal requirements.

Our environmental goals are based on our HSE policy. One of the most important criteria of these objectives is the minimization of emissions to certain environmental compartments.

We operate an Energy Management System (EMS) in accordance with the requirements of the ISO 50001 standard in the spirit of sustainable development.

In terms of energy awareness, we have invested significant amounts in recent years, by which we utilized large amounts of energy considered to be so-called waste heat in our production processes. Waste heat generated in the plants supplies thermal energy to the heating system of a significant part of our buildings and we are constantly expanding this solution. We continue to optimize the energy efficiency of our plants. Our energy-saving investments are both environmentally and economically beneficial, as reducing our demand for fossil fuels will also ensure a return on our environmental investments.

We provide a number of examples for our plant developments that support the achievement of our EMS objectives on our Sustainability Reports page.

In our procurement processes and investments, we give serious weight to energy consumption indicators and we also consider the greenhouse effect of a given material or applied technology during its lifecycle. In addition to corporate investments and processes, we also continuously develop the energy-conscious mindset of our employees.

In order to increase our efficiency, we reduce direct emissions by our technological developments, while the indirect emissions through increasing our energy efficiency.

We see the solution to the typical energy and GHG emission problems of the industry is working together. We are founding members of the Environmental Carbon-dioxide Partnership initiative, thus we have the opportunity to cooperate with domestic and foreign professionals, institutions, and companies to discuss the energy and GHG emission problems typical of the industry and search for solutions. Within the framework of the Partnership, there is an opportunity to promote innovation, joint tenders as well as closer and more efficient cooperation. Our main activities include exploring the applicability of CCU (Carbon Capture and Utilization) technologies, researching the application of clean coal technologies, and elaborating on the possibilities of producing, using, and storing renewable energy. In the possession of technological results, we examine the conditions for the effective applicability of the methods, the social and economic conditions of the efficient feasibility of renewable energy-based raw material production in parallel with energy storage, and examination of the impact of circular energy management exercised on consumption and its social significance.

Within the framework of the Partnership, our opportunities are not limited to carbon dioxide research; we can also deal with other environmental tasks.

The wastewaters generated in our plants and technological processes are pre-treated at the point of the generation prior to containment at the central Wastewater Treatment Plant.

We have a wastewater treatment patent based on the combined use of chemical and biological treatment. With the help of our innovative salty wastewater treatment technologies, an organic matter-free brine is produced from the wastewater of our plants with high salt content. Due to its high purity, it can be recycled at the beginning of our production process in accordance with the principles of the circular economy, thus reducing the consumption of raw material and energy, as well as generating wastewaters and wastes.

During the neutralization of our alkaline and saline wastewaters, the resulting brine is crystallized and then the recovered salt is reused at the beginning of our production process, in electrolysis. With this purification method, we produce crystallized salt that far exceeds the quality and purity of industrial salt obtained from salt mines, thus reducing our GHG emissions from mining and transportation of the raw material, our environmental load, and the amount of imported rock salt raw material. The energy demand of the cleaning process is covered by the so-called waste heat generated during the chemical reactions in our plants, thus reducing losses and making the most of the opportunities provided by our technologies. By utilizing the waste heat, the construction of cooling water circles and their operational losses can also be avoided.

During the development of our VCM Plant, we also tried to take full advantage of the opportunities provided by recycling. We have developed our unique catalytic oxidation wastewater treatment system, taking into account the circular economy principles. The organic matter content of the wastewater generated during the technological process is decomposed with the help of OOS (out of specification) hypo, therefore we utilize hypo, which otherwise would go to waste disposal. By recycling OSS hypo back into the purification system, we also reduce the environmental load and our own use of commercial-grade hypo.

Thanks to the careful designing of our engineers, the salty wastewater treatment of our VCM Plant has also become more sustainable. Subsequent to treatment, the salty wastewater generated at the plant is recycled in our systems. As part of our ongoing investment, we are building a new chemical oxidation unit to expand the circular solutions for salty water treatment.

For more information on our R&D activities related to wastewater treatment, please visit our Technology development page.

We take into account the Natura 2000 classified sites located near our Company and their important role as an ecological corridor. Based on the biological surveys carried out in our impact area, we have more and more knowledge about the area’s biodiversity. Due to developments in recent years, the surveys cover the ecological status assessment of aquatic life, terrestrial flora, fauna, lichens, and the inspection of bird migration areas.

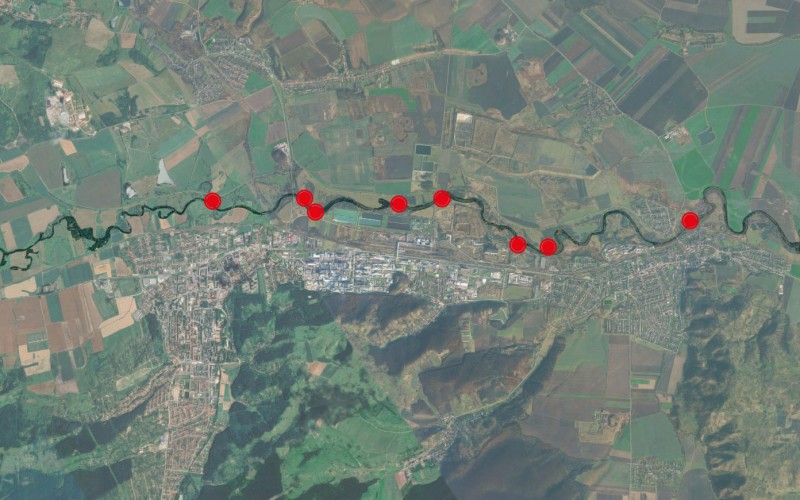

Our goal is to preserve and improve the biological condition of the Sajó Valley and the River Sajó and voluntarily study our effects exercised on different groups of organisms in cooperation with environmental organizations, To this end, we regularly monitor the ecological status of the River Sajó and the bird fauna.

For more information, please visit our Sustainability Reports page.

The River Sajó, located in the immediate vicinity of our site, is of prime importance for the operation of our Company, as it provides the necessary amount of water for our operations. In addition to the quantitative and qualitative analysis of the river, BorsodChem also conducts an annual condition survey. The main purpose of the study is to monitor any changes that may have occurred in the ecological status of the River Sajó. Based on the EU Water Framework Directive, which sets priorities for water management and water protection, we aim to achieve, maintain, and ensure a good ecological status in the long run. Because of several years of continuous research, we now have a data set of more than ten years, which enables us to identify trends that are unique on a national scale.

During the ecological baseline status assessment of affected and background areas, groups of organisms at different levels of the food chain are examined to provide us a comprehensive picture of the impacts affecting the given area. The results of assessing the ecological status of certain fish species show a slight improvement compared to the results of the previous year.

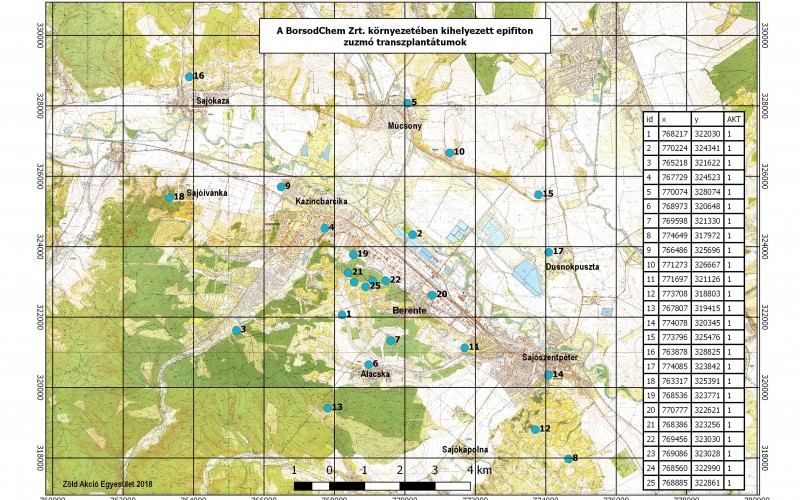

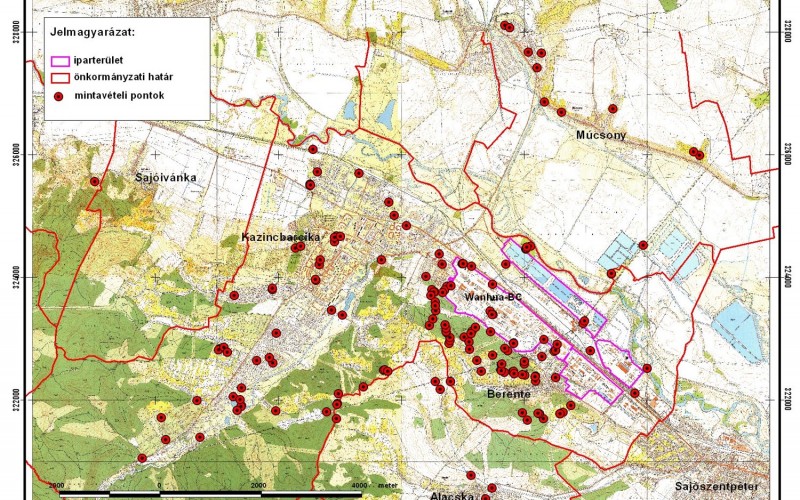

We pay special attention to monitoring and continuously improving air quality in our environment. In addition to air-quality instrumentation measurements, we have been conducting biomonitoring since 2015 with the support of external experts.

As part of our biomonitoring activities conducted in collaboration with our external expert partner, a baseline survey was performed both at loaded and background points. Data were collected at 166 sampling points around BorsodChem and the neighbouring settlements of Kazincbarcika, Berente, and Múcsony. 42 lichen species and 5 lichen populations were identified. Based on the composition and the health status of the lichens a so-called lichen map was set up.

As there was no elemental analysis of lichen in the area before, therefore the results of the samples could not be compared to other similar measurements. In addition, it is difficult to identify the source of impacts, since in the case of bio-indicators the pollutants from different sources appear as cumulative effects (transport, industry and residential activity, etc.). Due to the specific nature of biomonitoring, we will repeat the status assessment every 4-5 years.

Our Company's Wastewater Treatment Plant has six basins, three of which are popular with waterfowls. Here, due to water temperatures around 6°C, some of the basins freeze only during extremely cold periods, consequently, the waterfowl population can use the water surfaces for wintering and as a temporary residence.

In close cooperation with the Aggtelek National Park Directorate, we have been conducting surveys on our wastewater averaging and saline lagoons since the mid-2000s. From a conservation point of view, it is extremely important to preserve these bird habitats, where several highly protected bird species regularly nest, including gulipans, stingrays, buffalo, and red-footed hornbills. BorsodChem, in cooperation with the National Park, supports the survival of rare bird species as a voluntary principle and objective when planning the recultivation activity. For this reason, the elimination of basins has been and will be carried out with maximum consideration of nature conservation aspects.

During 2017-2018, 67 bird species could be observed in the basins of our wastewater treatment plant and in their immediate vicinity.

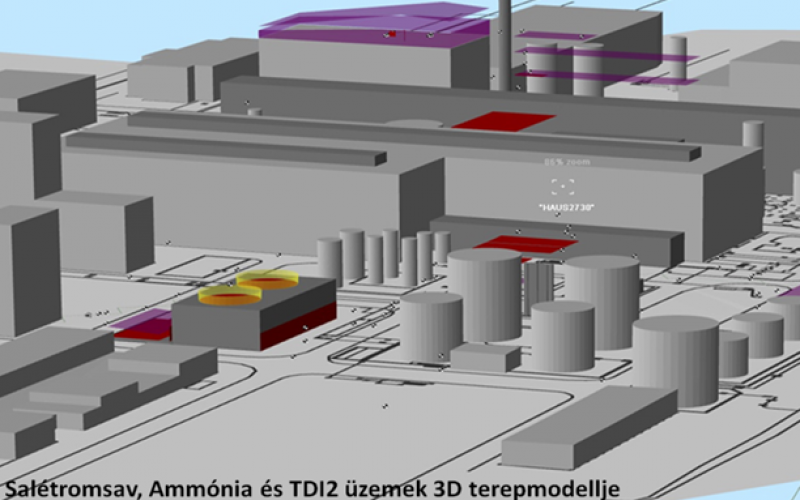

Due to the residential areas close to our site, we need to pay accelerated attention to our noise impacts and their reduction. For this purpose, we are implementing an overall noise reduction project also approved by the Authority with the aim of complying with the increasingly stringent noise protection limit values and policies. As a first step, we prepared a 3D noise map covering our entire site in Kazincbarcika. Based on this map, we developed a 3-phase action plan, which aims to reduce noise at our entire plant site within nearly 10 years.

In the first phase of the project, we identified and assessed the types and locations of noise sources, which trigger limit value overrun, then based on the results, we created a 3D model of our production sites and their surroundings. The software model allows the preliminary assessment and planning of various noise sources and impacts, as well as their effective monitoring. The first phase was closed at the end of 2019. After evaluation of the first phase, in 2020 we started the implementation of the second phase technical interventions.

You can find our HSE Policy and Objectives on our Policies page.

For detailed information on environmental protection, please visit our Sustainability Reports page.

.JPG)